FXE Series

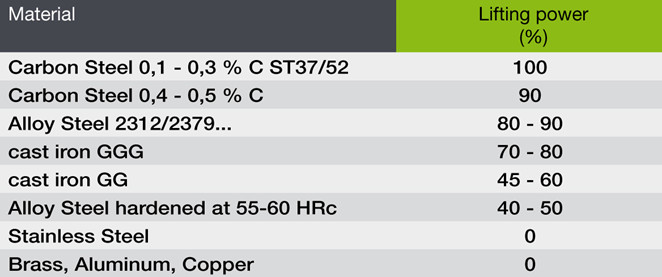

Electro-permanent FXE technology offers maximum safety in magnetic lifting applications. This technology combines the advantages in terms of reliability of permanent magnets and the easy use of electromagnets. The electric current is used only for a few seconds during the activation and deactivation of the magnetic circuit. Even in the event of breakage of the power cable or loss of power from the mains, the load is never released by the lift.

Flexibility and easy use distinguish the product in its multiple versions and applications. FXE uses electro-permanent magnetic technology, i.e. the current is used only to activate or deactivate the system and not during the work phase.COMPLETE RANGE

FXE 50

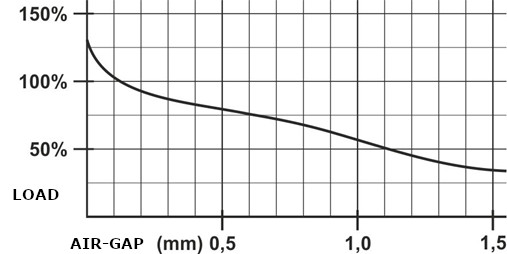

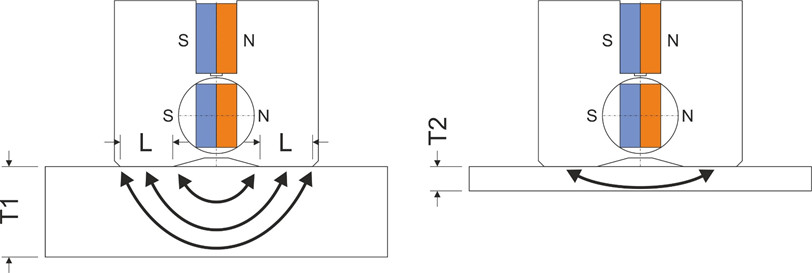

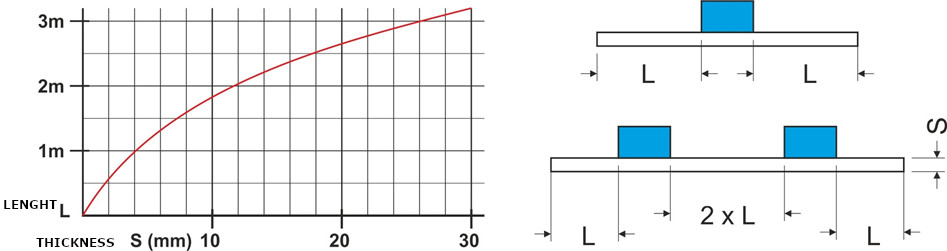

Lifting modules equipped with Pole Type 50 with a load capacity of 300 to 1600 kg. Pole Type 50 is designed to lift materials starting from 4 mm thick with flat surfaces. The nominal flow values are calculated with an air gap of 0.3 mm. With air gap 0, the Pole Type 50 achieves a holding force of 3.8 kN per pole.

FXE-L 50+

Lifting modules equipped with Pole Type 50+ with a load capacity from 400 to 1000 kg. Pole Type 50+ has a reinforced magnetic system for medium rough surfaces. With air gap 0, the Pole Type 50+ achieves a holding force of 3.8 kN per pole.

FXE 80

Lifting modules equipped with Pole Type 80 with a load capacity from 1000 to 4000 kg. Pole Type 80 is designed to lift loads starting from 8 mm thick with medium rough surfaces and medium air gaps. The nominal flow rates of the FXE Pole Type 80 are calculated with an air gap of 0.4 mm. With air gap 0, the Pole Type 80 achieves a holding force of 9 kN per pole.

FXE-100

Lifting modules equipped with Pole Type 100 with a load capacity of 1600 to 7200 kg. Pole Type 100 is designed to lift loads starting from 12 mm thick with particular shapes or forged with large air gaps. The nominal flow rates of the FXE Pole Type 100 are calculated with an air gap of 0.6 mm. With air gap 0, the Pole Type 100 achieves a holding force of 14.5 kN per pole.

FXE-R

FXE-R magnetic modules can lift round or flat materials. We create these modules starting from the FXE base with special polar shoes that we can customize for single sockets or in layers.

FXE-Z

Thanks to a special magnetic circuit, the FXE-Z modules have an additional ability to demagnetize the piece after handling. With this module, the pieces that have residual magnetism can be degaussed after handling by the module itself.

FXE-T

Magnetic beam with electro-permanent lifting modules for sheet metal, with load capacity from 2500 to 6400 kg. and formats max. 6000x2000mm.

FXE-M

The FXE-M electro-permanent magnetic modules can be connected with the MCF control unit to create modular lifting systems. They are made with monobloc technology and are extremely robust. Wide range of choice of magnetic modules in relation to the specific application.