FX Series

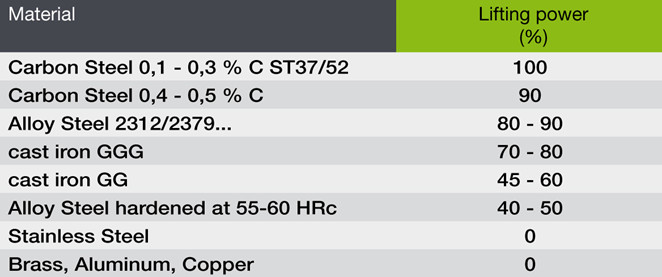

Permanent lifting magnets work without the need for external energy supply; they are activated manually via an operating handle and are the most commonly used lifting magnets. Permanent lifting magnets are suitable for lifting and moving individual loads such as sheet metal, rough parts, forgings, castings and profiles with a load capacity of up to a maximum of 3 tons and are used in all industrial sectors wherever iron metal parts need to be handled.

COMPLETE RANGE

FX UNIVERSAL

The most versatile range of lifters for multiple types of use from 150 to 3000Kg.

FX R

A range of lifters specific for round loads from 100 to 1800Kg and from 25 to 560 mm. in diameter

FX P

A range of lifters specific for pipes and thin thicknesses from 170 to 1650 kg

FX VV

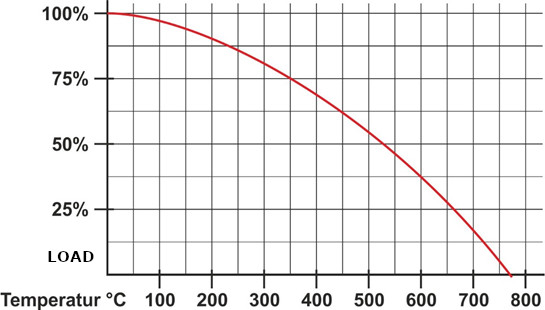

A range of lifters specific for profiles with a 90° angle and hot parts up to 150°C from 200 to 800Kg.

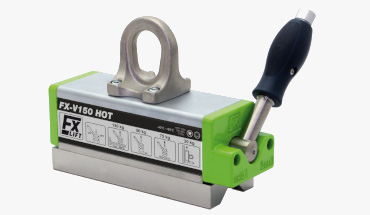

FX VV HOT

A range of lifters specific for hot parts up to 250°C from 150 to 600Kg

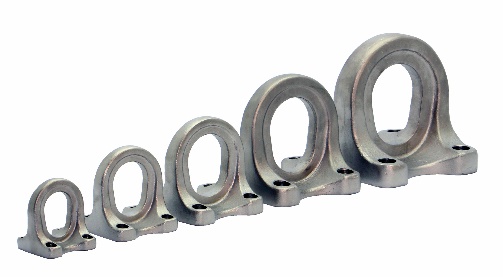

FX C

A range of lifters specific for flanges, sleeves and discs from 175 to 450Kg

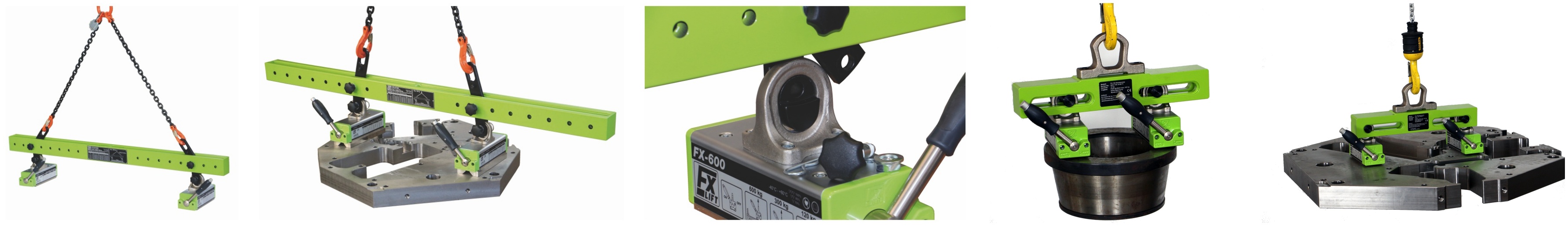

FX ACCESSORIES

- FX-HV Horizontal-Vertical system from 150 to 3000Kg

- FX-HVS Tilting horizontal-vertical system.,

- FX-LT Magnetic lifting beam from 600 to 4800Kg

- FX-KT Small Magnetic lifting beam from 240 to 480Kg